Preventing Freezer Burn with Bubble Backed Ice Packs

A common concern, when transporting cold sensitive goods, is product freezer burn. For goods such as baking or ready cooked meals, fresh vegetables, fruits, and meat, as well as biological specimens such as blood, freezer burn will affect the quality, especially when contained inside a carton in close proximity to a coolant. Ensuring the integrity and quality of your product during transit is essential to preserving freshness and life.

It is not widely understood how freezer burn occurs or how to combat this. The direct contact of frozen gel ice packs on cold sensitive, fresh product for an extended period of time is what commonly causes freezer burn during transit. Freezer burn can be identified as tough, shriveled, and discoloured or frozen spots on the affected product, and is the result of moisture loss. Although technically still edible, the product has an off texture and taste, and appears extremely unappetizing, meaning the affected product is typically cast away. This can also happen in the transportation of pharmaceutical products where the goods being shipped are chilled too fast or chilled to low resulting in the product being ineffective and a spoiled shipment.

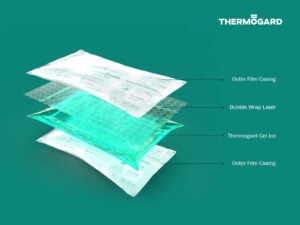

If ‘freezer burn’ is an issue facing your business in your cool-chain transit, bubble backed gel ice packs are an easy solution. These gel ice packs are of the same design and components as standard gel ice packs, but with an additional benefit of a bubble wrap layer encased inside the lining. This bubble wrap layer not only provides an extra layer of cushioning for your product, but also means there is no direct contact between your product and the frozen gel component of the ice pack. The bubble wrap layer acts as a barrier between the frozen gel and the product, allowing cool air to flow between the product and the gel pack but not burn the product in any way.